An essential oil is a concentrated, hydrophobic liquid that carries the aromatic compounds of plants. These compounds are volatile, meaning they easily evaporate at normal temperatures. Essential oils are also referred to as volatile oils, ethereal oils, aetherolea, or simply the natural oil derived from the source plant.

The most common method of obtaining essential oils is through distillation, with steam distillation being widely used. At Glass Reactor, we offer advanced equipment to produce high-quality essential oils efficiently. Our solutions include: Steam Distillation Unit & Vacuum Distillation Unit.

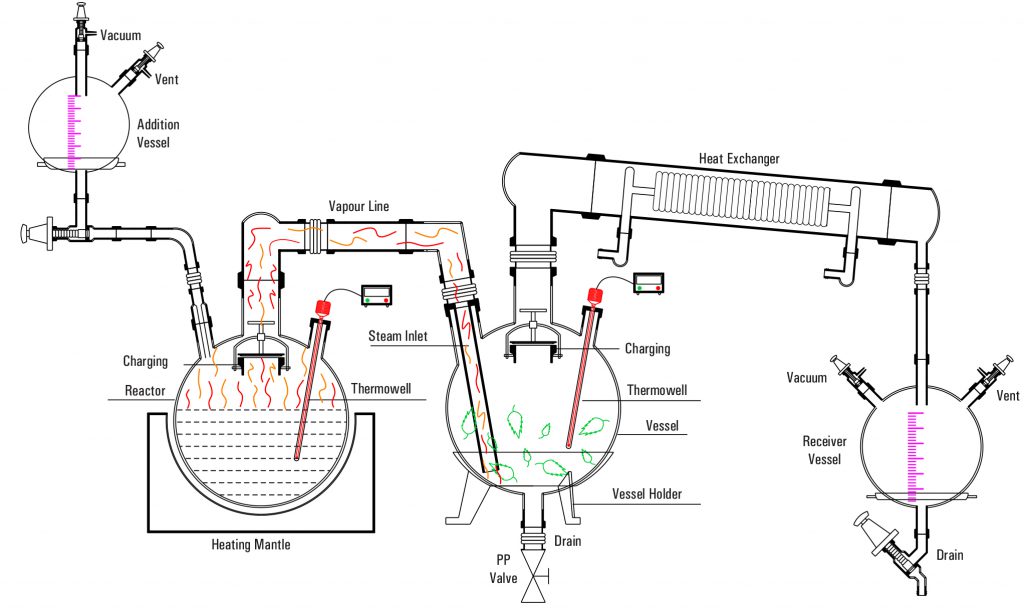

1. Steam Distillation Unit

Our essential oil distillers are offered in a range of vessel capacities including 10, 20, 50, 100, and 200 liters, making them versatile for both atmospheric and full vacuum operations.

Steam distillation is a widely used method for separating components by distilling water along with other volatile and non-volatile substances.

In this process, water is heated separately in the spherical vessel. The generated steam passes into the reactor, where it interacts with plant material such as leaves, flowers, or wood. The steam captures the volatile compounds and carries them to a condenser. Here, the vapor cools and condenses back into liquid form, while non-volatile residues remain in the reactor for collection and disposal.

|

Unit Cat. Ref. |

Reactor Capacity |

Mantle KW |

Addition Vessel |

Condenser HTA (M2) |

Receiver Vessel |

|

EOSD 10 |

10 L |

1 |

5 L |

0.35 |

5 L |

|

EOSD 20 |

20 L |

1.8 |

5 L |

0.50 |

5 L |

|

EOSD 50 |

50 L |

3.6 |

20 L |

1.50 |

20 L |

|

EOSD 100 |

100 L |

5.4 |

20 L |

1.50 |

20 L |

|

EOSD 200 |

200 L |

8.1 |

50 L |

2.25 |

50 L |

Our Essential Oil Distillers are engineered to deliver consistent performance, easy operation, and long-term durability. Whether you are a small-scale producer or an industrial manufacturer, our distillation units are tailored to meet your production requirements, ensuring the finest quality essential oils every time.