Goel Impex designs and manufactures high-performance distillation columns that ensure efficient separation and purification of liquid mixtures. Our industrial distillation columns are engineered with durable borosilicate glass, making them ideal for both laboratory and large-scale applications.

A distillation column is a vital part of any distillation system used to separate components of a liquid mixture based on their boiling points. It is commonly used in chemical, pharmaceutical, and petrochemical industries to achieve high-purity products. The working principle of a distillation column is based on vapor-liquid equilibrium, where rising vapors interact with descending liquid, allowing separation of components.

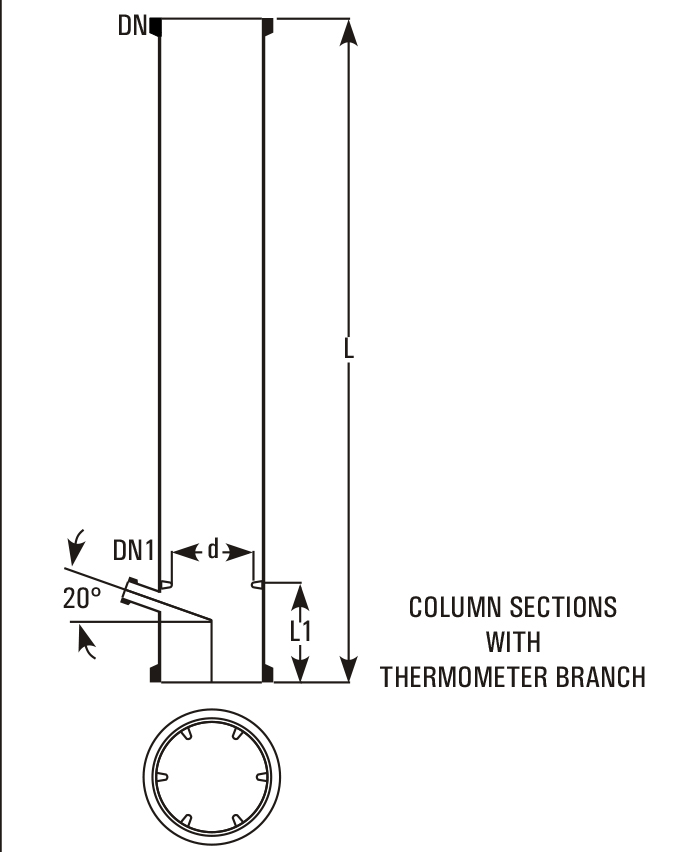

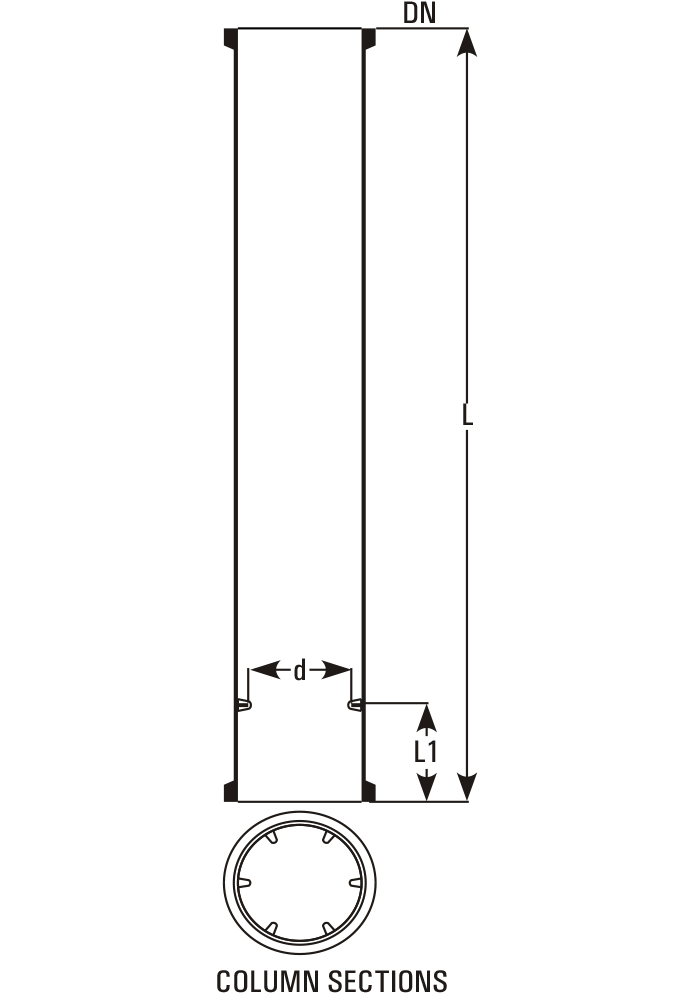

Our distillation column design focuses on durability, transparency, and performance. These columns can be constructed using pipe sections with support plates or column sections with packing supports. Each column is provided with a fused shelf where the packing support rests securely, ensuring stable operation under varying pressure and temperature conditions.

Key Features of Glass Distillation Columns

• High-quality borosilicate glass construction

• Modular design for easy assembly and cleaning

• Available in various diameters and lengths

• Compatible with tray or packed column configurations

• Designed for both continuous and batch distillation processes

|

Cat. Ref. |

DN |

L |

L1 |

Minimum packing Size |

Usual packing Size |

|

CS3/1000 |

80 |

1000 |

75 |

9 |

12 |

|

CS4/1000 |

100 |

1000 |

75 |

12 |

15 |

|

CS6/1000 |

150 |

1000 |

75 |

15 |

25 |

|

CS6/1500 |

150 |

1500 |

75 |

15 |

25 |

|

CS9/1000 |

225 |

1000 |

100 |

20 |

25 |

|

CS9/1500 |

225 |

1500 |

100 |

20 |

25 |

|

CS12/1000 |

300 |

1000 |

100 |

25 |

25 |

|

CS12/1500 |

300 |

1500 |

100 |

25 |

25 |

|

CS16/1000 |

400 |

1000 |

150 |

25 |

25 |

|

CS16/1500 |

400 |

1500 |

150 |

25 |

25 |

|

CS18/1000 |

450 |

1000 |

150 |

25 |

25 |

|

CS18/1500 |

450 |

1500 |

150 |

25 |

25 |

|

CS24/1000 |

600 |

1000 |

200 |

40 |

40 |

Goel Impex offers a wide range of distillation column types based on industrial needs:

1. Packed Distillation Column – Uses packing materials for improve contact between vapor and liquid.

2. Tray Distillation Column – Equipped with trays or plates for stepwise separation.

3. Vacuum Distillation Column – Designed for heat-sensitive compounds at reduced pressure.

4. Multi-Column Distillation Plant – Ideal for large-scale production and high-purity outputs.

5. Lab Distillation Column – Compact setup for laboratory-scale operations.

6. Stainless Steel Distillation Column – For demanding chemical environments requiring robust construction.

Distillation Column Parts and Components

Our columns come with precisely designed distillation column parts, including:

• Column sections and flanges

• Packing supports and distributors

• Trays and packing materials

• Reboilers and condensers

• Temperature and pressure gauges

Applications of Distillation Columns

Our distillation column systems are widely used in:

• Chemical and pharmaceutical production

• Essential oil and solvent recovery

• Water purification and alcohol distillation

• Petrochemical and biofuel industries

As a trusted distillation column manufacturer and supplier, Goel Impex is known for:

• Superior-quality glass engineering

• Custom design and fabrication services

• Compliance with international quality standards

• Excellent after-sales support and service

Whether you require a lab-scale distillation column or an industrial distillation column system, Goel Impex delivers customized solutions for every process need. Reach out today to discuss your project requirements or request a quotation.

The distillation column can be equipped with a thermometer branch positioned just below the packing shelf. This branch is installed at a 20° angle, allowing accurate temperature measurement during the distillation process and ensuring precise monitoring of column performance.

|

Cat. Ref. |

DN |

DN1 |

L |

L1 |

d |

|

CST3/1000 |

80 |

25 |

1000 |

125 |

50 |

|

CST4/1000 |

100 |

25 |

1000 |

125 |

75 |

|

CST6/1000 |

150 |

25 |

1000 |

125 |

125 |

|

CST6/1500 |

150 |

25 |

1500 |

125 |

125 |

|

CST9/1000 |

225 |

25 |

1000 |

150 |

175 |

|

CST9/1500 |

225 |

25 |

1500 |

150 |

175 |

|

CST12/1000 |

300 |

25 |

1000 |

150 |

250 |

|

CST12/1500 |

300 |

25 |

1500 |

150 |

250 |

|

CST16/1000 |

400 |

25 |

1000 |

200 |

250 |

|

CST16/1500 |

400 |

25 |

1500 |

200 |

350 |

|

CST18/1000 |

450 |

25 |

1000 |

200 |

400 |

|

CST18/1500 |

450 |

25 |

1500 |

200 |

400 |

|

CST24/1000 |

600 |

25 |

1000 |

250 |

540 |