A shell and tube heat exchanger is one of the most efficient designs for transferring heat between two fluids. Known for its large surface area, compact design, and exceptional performance, this system is widely used across industries for heating, cooling, condensation, and evaporation processes.

Goel Impex is a leading glass shell and tube heat exchanger manufacturer in India, providing high-quality equipment made with precision-engineered glass components to ensure durability, corrosion resistance, and superior heat transfer efficiency. Our glass shell and tube heat exchangers are designed to meet diverse industrial requirements with outstanding reliability.

1. Excellent corrosion resistance: Made using high-quality borosilicate glass, it offers universal resistance against corrosive chemicals, making it an excellent alternative to costly materials such as graphite, copper, titanium, hastelloy, and tantalum.

2. Efficient heat transfer: Smooth glass surfaces minimize fouling and ensure consistent thermal performance.

3. Versatile installation: Suitable for both vertical and horizontal mounting depending on process requirements.

4. Easy maintenance: Tubes can be easily replaced or cleaned, reducing downtime and maintenance costs.

5. Wide range of heat transfer areas (HTAs): Available in multiple sizes and capacities for different industrial needs.

6. Lightweight and easy to install: The compact design allows easy handling and installation.

7. Economical and durable: Offers long service life with minimal maintenance.

8. Space-saving design: Ideal for setups requiring large heat transfer areas within limited space.

1. The heat transfer coefficient of a shell and tube type heat exchanger is nearly three times higher than that of a coil-type design.

2. The pressure drop in the shell and tube heat exchanger is significantly lower compared to 2–3 kg/cm² found in coil-type exchangers.

3. For processes requiring large heat transfer surfaces, the shell and tube heat exchanger remains the most efficient and cost-effective choice.

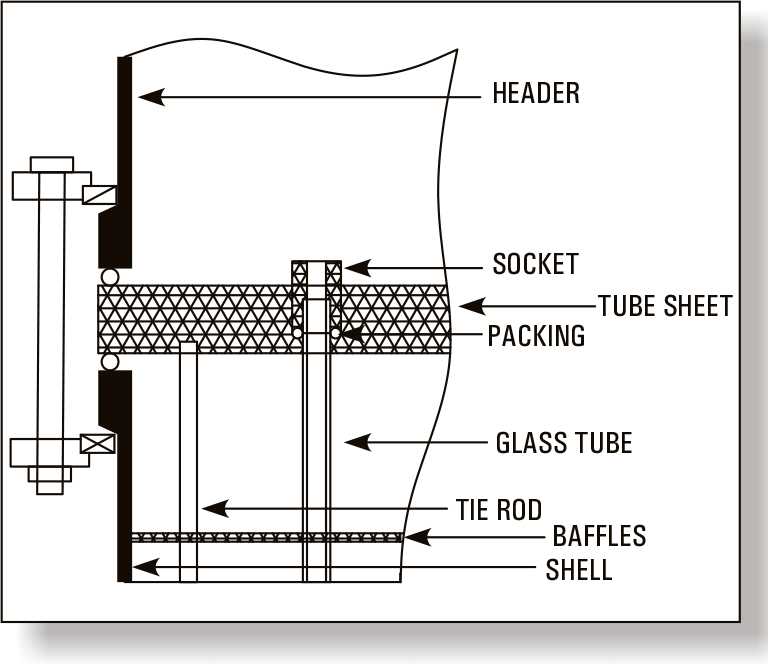

Each glass tube is individually sealed into a PTFE tube sheet using specialized PTFE sockets and packings. This unique ferrule-type sealing system ensures easy tube replacement and cleaning while maintaining leak-proof performance. Baffles on the shell side enhance turbulence, which improves heat transfer efficiency.

The exchangers are constructed using SCHOTT DURAN glass, known for its strength and chemical resistance. The seamless glass tubes offer excellent pressure ratings, ensuring reliability in various industrial applications.

You can refer to the shell and tube heat exchanger diagram for a better understanding of its design and construction.

– Made from SCHOTT DURAN.

– Joint less tubes offer better pressure rating

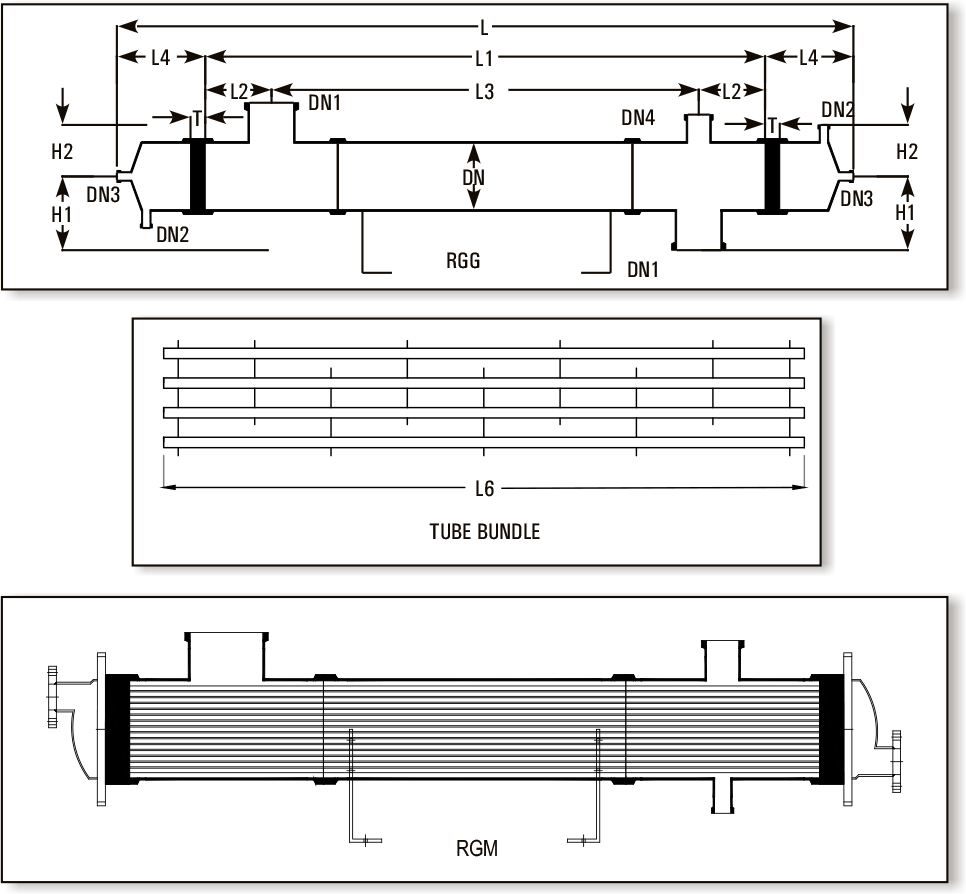

TYPE:

Three basic versions * are available :

|

Material Of Construction of Shell & Tube Heat Exchanger |

||||

| Model | Shell | Tube | Header | Duty |

| RGG | Glass | Glass | Glass | For heat transfer between two aggressive media. |

| RGM | Glass | Glass | Steel/FRP | For heat transfer between aggressive media in shell & non-aggressive media in tubes. |

| RMG | Steel/FRP | Glass | Glass | For heat transfer between aggressive media in tubes & non-aggressive media in shell |

|

* GOEL provides assistance to clients for selecting the right model for specific duty. |

||||

|

Cat.Ref. |

6/3 |

6/4 |

6/5 |

6/6 |

9/6 |

9/8 |

9/10 |

9/12 |

12/12 |

12/16 |

12/21 |

12/25 |

|

Area (m2) |

3 |

4 |

5 |

6 |

6 |

8 |

10 |

12 |

12 |

16 |

21 |

25 |

| DN |

150 |

225 |

300 |

|||||||||

| DN1 |

80 |

100 |

150 |

|||||||||

| DN2 |

50 |

80 |

80 |

|||||||||

| DN3 |

25 |

40 |

40 |

|||||||||

| DN4 |

50 |

50 |

50 |

|||||||||

| H1 |

175 |

250 |

300 |

|||||||||

| H2 |

150 |

200 |

250 |

|||||||||

| L |

2500 |

3100 |

3700 |

4300 |

2620 |

3220 |

3820 |

4520 |

2550 |

3150 |

3950 |

4550 |

| L1 |

1900 |

2500 |

3100 |

3700 |

1900 |

2500 |

3100 |

3800 |

1800 |

2400 |

3200 |

3800 |

| L2 |

150 |

150 |

150 |

150 |

225 |

225 |

225 |

225 |

225 |

225 |

225 |

225 |

| L3 |

1600 |

2200 |

2800 |

3400 |

1450 |

2050 |

2650 |

3350 |

1350 |

1950 |

2750 |

3350 |

| L4 |

250 |

250 |

250 |

250 |

300 |

300 |

300 |

300 |

300 |

300 |

300 |

300 |

| L5 |

125 |

125 |

125 |

125 |

175 |

175 |

175 |

175 |

175 |

175 |

175 |

175 |

| L6 |

1980 |

2580 |

3180 |

3780 |

2000 |

2600 |

3200 |

3900 |

1930 |

2530 |

3330 |

3930 |

| T |

50 |

60 |

75 |

|||||||||

| No. of Tubes |

37 |

73 |

151 |

|||||||||

| No. of Baffles |

11 |

15 |

19 |

23 |

7 |

9 |

13 |

17 |

5 |

7 |

9 |

11 |

1. Permissible temperature range for both shell and tube sides: –40°C to +150°C.

2. Maximum temperature difference between shell and tube sides: 120°C.

3. Suitable for full vacuum operations on both sides.

Maximum limiting pressures are tabulated here below:

|

Maximum Permissible Pressure Range, Kg/cm2(g) |

||||

| Model |

Side |

150DN |

225DN |

300DN |

| RGG |

Shell |

2.0 |

1.0 |

1.0 |

| RGM |

Shell |

2.0 |

1.0 |

1.0 |

| RMG |

Shell |

3.5 |

3.5 |

3.5 |

The shell and tube heat exchanger is designed for a wide range of chemical and pharmaceutical processes. Goel Impex provides customized designs based on the relationship between pressure, temperature, and required heat transfer area, ensuring optimal performance for every application.

The glass shell and tube heat exchanger provides outstanding heat transfer performance due to its efficient flow dynamics. The correlation between fluid velocity and heat transfer efficiency can be observed through the shell and tube heat exchanger working principle and its detailed design data.

With a variety of types of shell and tube heat exchangers, Goel Impex ensures precise engineering, quality materials, and superior workmanship to deliver durable and high-performance equipment for industrial needs.

For approximate sizing some typical heat transfer coefficients are given here below:

|

U-Values |

||||

| Media |

Use |

kcal/m2hrk |

W/m2k300 |

|

| DN | ||||

| Steam water |

condensation |

350-550 |

410-640 |

|

| Water – water |

cooling |

250-350 |

290-410 |

|

| Water – air |

cooling |

30-60 |

35-70 |

|

As a reputed shell and tube heat exchanger manufacturer and supplier in India, Goel Impex offers a comprehensive range of glass heat exchangers, including:

– Glass shell and tube heat exchangers

– Shell and tube type glass heat exchangers

– Glass lined heat exchangers

Every product is tested for quality and performance to meet international standards. Whether you need a standard model or a customized shell and tube heat exchanger design, we deliver dependable solutions at competitive prices.