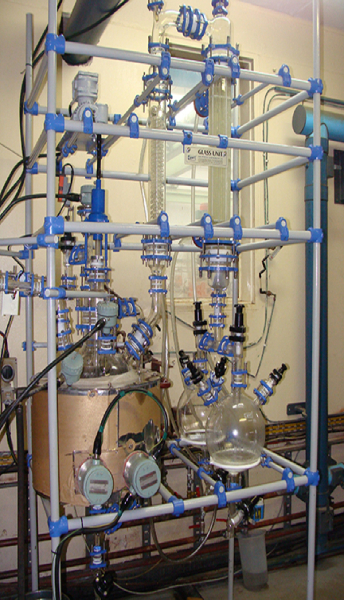

Kilo Lab Glass Reactors are versatile pilot plant systems designed to handle a wide range of chemical processes efficiently. Each Glass Reactor and Distillation Unit is built with essential functionalities such as precise heating, controlled stirring, effective condensation, fractionation, and reliable cooling, ensuring smooth and safe operation across applications.

From a design perspective, these units are referred to as Kilo Labs, but in practical terms, they serve as flexible multi-purpose systems that adapt to various process requirements. This adaptability makes them ideal for use in research laboratories, educational institutes, pharmaceutical development, and chemical industries.

The modular design of the Kilo Lab Glass Reactor allows easy customization or reconfiguration to suit specific experimental or production needs. Users can modify the setup quickly without compromising performance or safety.

Constructed using high-quality borosilicate glass, these reactors provide excellent chemical resistance, superior transparency for process observation, and ease of cleaning, ensuring durability and reliability in demanding environments.

At Goel Impex, we deliver Kilo Lab systems that combine innovation, quality, and functionality to support efficient process development and scale-up operations.