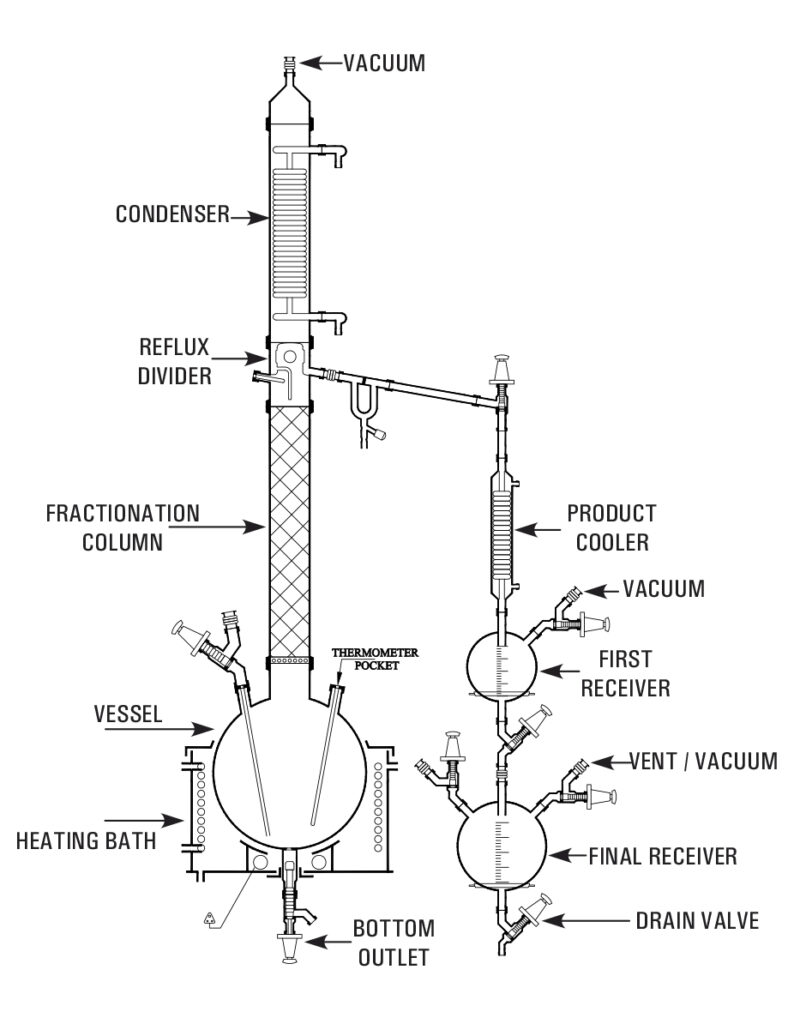

Fractional distillation is implemented in a compact, batch-style unit. The bottom section acts as a reboiler, a vessel immersed in a heating bath, while a packed column is mounted above it. Vapor generated in the reboiler ascends through the packed column, undergoing repeated vaporization and condensation (fractionation) to improve separation.

At the column top, vapors are condensed and, depending on the desired reflux ratio, part of the condensate may be returned down the column as reflux and part withdrawn as product. The top product is cooled (sub-cooled) and collected in receivers, while the heavier (bottom) fraction is drained from the reboiler through a valve.

Our fractional distillation units are offered in vessel capacities of 20 L, 50 L, 100 L, and 200 L. They are engineered for operation under atmospheric pressure or under full vacuum, making them versatile across various lab and pilot setups.

Below you may place a clear fractional distillation diagram illustrating the arrangement: reboiler, packed column, reflux line, condenser, receivers, etc.

|

Unit |

Reactor |

Bath |

Addition |

Vapour |

Conderser |

Cooler HTA M2 |

Receiver |

|

FDU20 |

20 L |

4.0 |

2 L |

80 DN |

0.35 |

0.10 |

5L |

|

FDU50 |

50 L |

6.0 |

5 L |

100 DN |

0.50 |

0.20 |

10L |

|

FDU100 |

100 L |

9.0 |

10 L |

150 DN |

1.50 |

0.35 |

20L |

|

FDU200 |

200 L |

12.0 |

20 L |

150 DN |

1.50 |

0.35 |

20L |

|

FDU300 |

300 L |

18.0 |

20 L |

225 DN |

2.50 |

0.50 |

20L |

|

FDU500 |

500 L |

24.0 |

50 L |

300 DN |

4.00 |

0.70 |

50L |

In the design of a fractional distillation apparatus for Goel Impex / Goel’s Kilo Lab, the following are key:

• A robust fractional distillation column filled with appropriate packing to promote multiple theoretical stages

• Efficient vapor–liquid contact zones to drive separation

• Provision for reflux control

• Condenser(s) sized to handle the vapor load

• Temperature sensors and valves to monitor and control the process

• Corrosion-resistant glass (borosilicate) and PTFE wetted parts to ensure purity and compatibility

The fractional distillation method ensures that components with closer boiling points can be separated more effectively than via simple distillation. The principle of fractional distillation is that, in each vaporization–condensation cycle inside the column, the more volatile component becomes enriched in the vapor phase, while the less volatile condenses and returns downward.