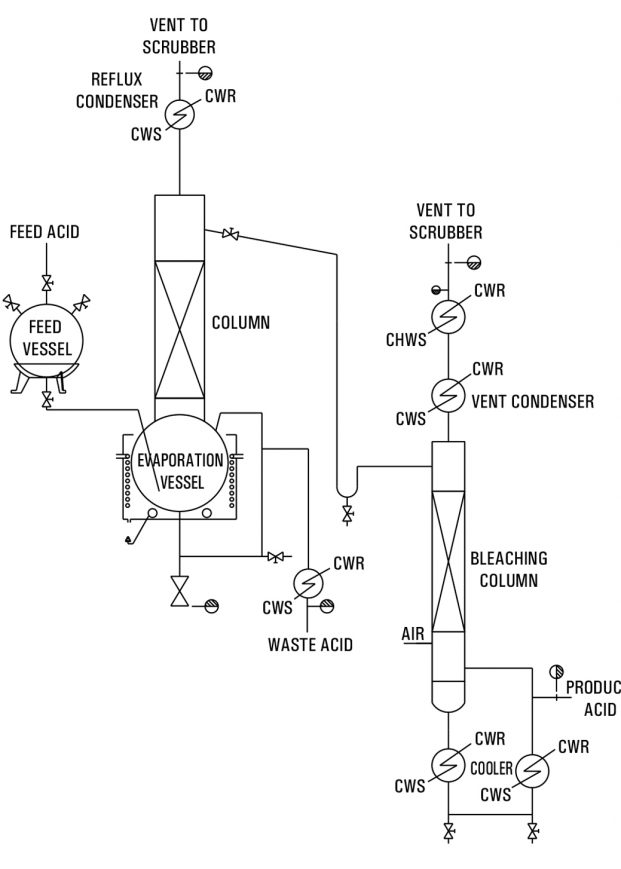

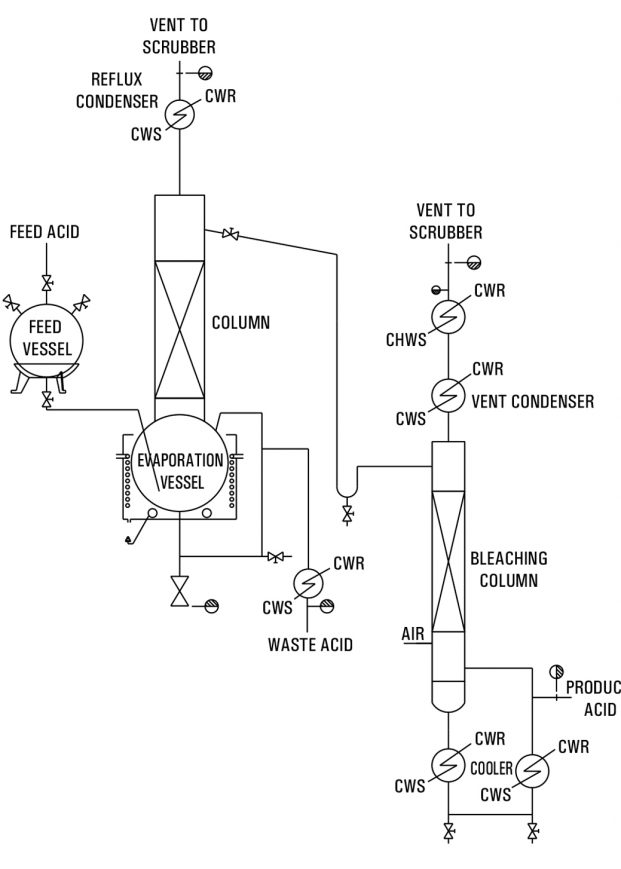

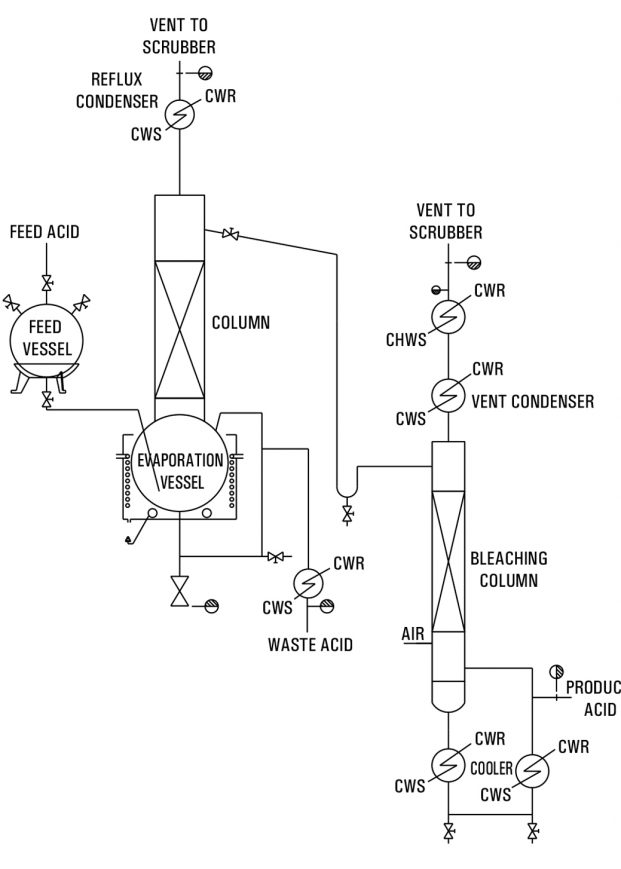

The purification of industrial or technical grade nitric acid is achieved through a single-stage distillation process that separates non-volatile impurities, leaving them behind in the still residue.

Nitric acid with a concentration of 69% to 70% is fed from the storage tank to the glass distillation still using a metering pump. The still is equipped with an electrically heated oil bath, ensuring consistent thermal control during the distillation process.

The generated acid vapors pass through a mist eliminator section and are then directed into a high-efficiency glass condenser. To achieve the desired concentration, high-purity water may be added as a diluent to the condensed nitric acid before it flows into the bleaching column.

At the base of the bleaching column, clean air is introduced to assist in removing nitrogen oxides. The mixture of air and nitrogen oxides is then vented through a secondary condenser and sent to a scrubber unit for safe treatment.

Entrained nitric acid is collected separately instead of being returned to the bleaching column, ensuring purity. This process effectively eliminates all NOx traces, producing high-grade, purified nitric acid suitable for electronic and laboratory applications.

Our Nitric Acid Purification System is designed to deliver reliable performance, consistent concentration, and superior purity standards for various industrial and scientific uses.

Design Basis & Requirement of Utilities :

|

Capacity |

40 |

kg/hr |

|

Commercial grade |

44 |

kg/hr |

|

Electric Heater |

48 |

kw |

|

Cooling Water @ 7 deg. C* |

4-5 |

Cu.M/hr |

|

Space Requirement |

3 x 3 x 8 m |

|