A Rotary Evaporator, also known as a Rotary Vacuum Evaporator, is an advanced thin film evaporation system designed for efficient and gentle removal of solvents from samples by evaporation under vacuum conditions.

In a rotary evaporator, the rotating flask forms a continuous thin film of liquid over a large surface area, enabling rapid and efficient heat transfer.

This thin film ensures consistent heating and prevents localized overheating. The use of vacuum conditions allows evaporation to occur at much lower temperatures than under atmospheric pressure, protecting heat-sensitive substances from degradation.

The result is a process that reduces both boiling point and residence time, making the rotary vacuum evaporator ideal for concentrating, purifying, or recovering solvents from delicate materials.

Rotary evaporators are widely used for crystallization, drying of granules or powders, and solvent recovery in research, pilot, and industrial-scale operations.

Goel Impex's Rotary Film Evaporators (GRFE) are trusted by laboratories, pilot plants, and production facilities across the chemical, pharmaceutical, and biotechnology industries.

A Rotary Evaporator operates as a precision thin film evaporator, commonly referred to as a Rotary Vacuum Evaporator, designed for fast and uniform solvent removal under controlled conditions.

1. Superior resistance to corrosion.

2. Digital display for rotation speed and bath temperature with auto control.

3. Process time indicator with digital readout.

4. Automated bath lifting mechanism.

5. Automatic lowering of bath during power interruptions for safety.

6. RS-232 communication interface (optional).

7. Designed to withstand complete vacuum conditions.

8. Perfectly suited for evaporation of heat-sensitive substances.

9. Reliable, maintenance-free operation.

10. Available in multiple capacities up to 400 litres.

Goel Impex Rotary Film Evaporator is a fully integrated unit comprising the following components:

1. A stainless steel (SS) heating bath equipped with precise temperature control and adjustable height mechanism.

2. A rotating borosilicate glass flask that ensures superior chemical resistance, connected to the drive assembly through a secure coupling.

3. A hollow glass drive shaft functioning as both the mechanical drive and vapor outlet, sealed with PTFE components for vacuum integrity. The drive motion is powered by a motor with variable speed control for flexibility.

4. A high-efficiency condenser and receiver assembly designed according to capacity and model specifications to achieve optimal condensation and solvent recovery.

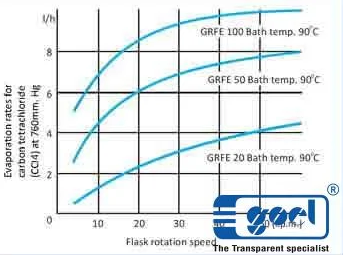

The performance of a Rotary Vacuum Evaporator depends on multiple parameters such as flask volume, rotational speed (RPM), bath temperature, and vacuum level.

The rate of solvent evaporation, as indicated by the boil-up rate for carbon tetrachloride (CCI₄), varies across models of 20L, 50L, and 100L, reflecting the superior efficiency of Goel Impex's systems in diverse operational setups.

Optional Accessories for Vacuum Evaporator:

1. Chiller System for precise cooling and condensation.

2. Vacuum Pump Assembly with tailored configuration for different evaporation requirements.

| Model | Rotating Flask Capacity (ltrs.) |

Rotating Speed (rpm) |

Electric Motor Rating |

Condense Cooling Area |

Receiver Flask Capacity (ltrs.) |

Power Supply (Volt/Hz) |

Bath Rating |

|---|---|---|---|---|---|---|---|

| GRFE2 | 2 | 0-80 | 40 Watt | 0.15 | 1 | 230 V, 50 Hz | 2 |

| GRFE3 | 3 | 0-80 | 40 Watt | 0.15 | 1 | 230 V, 50 Hz | 2 |

| GRFE5 | 5 | 0-80 | 40 Watt | 0.15 | 2 | 230 V, 50 Hz | 2 |

| GRFE10 | 10 | 0-80 | 0.25 HP | 0.20 | 5 | 230 V, 50 Hz | 4 |

| GRFE20 | 20 | 0-80 | 0.25 HP | 0.30 | 10 | 230 V, 50 Hz | 4 |

| GRFE50 | 50 | 0-80 | 0.25 HP | 0.50 | 20 | 230 V, 50 Hz | 6 |

The Goel Impex brand is recognized for its commitment to quality, reliability, and innovation, establishing itself as a leading trendsetter in the scientific equipment industry across India.

Goel Impex is synonymous with quality, innovation, and durability. Our rotary film evaporators are engineered to deliver consistent performance, reliability, and ease of operation.

From laboratory-scale research to industrial production, Goel Impex Rotary Vacuum Evaporators are built to meet the highest standards of process control and solvent recovery efficiency.