Bromine can be obtained from sources like sea bittern as well as industrial waste streams, such as aqueous HBr, NaBr, or KBr solutions.

The bromine content in different feedstocks can range widely, typically from 2 gpl to 300 gpl, depending on the industrial source.

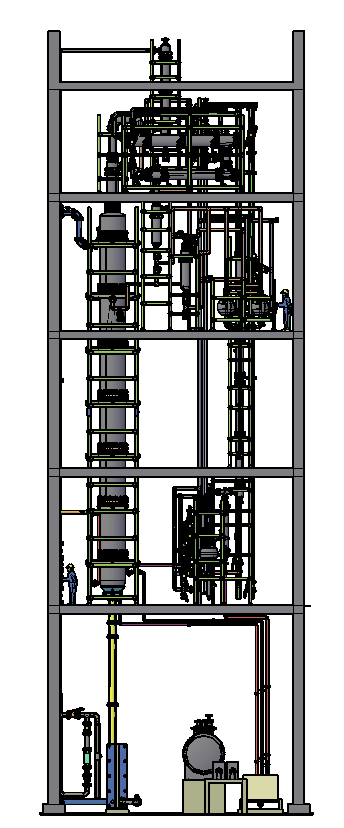

With over 20 years of experience, Goel designs and provides customized Bromine Recovery Plants suited for a variety of feedstocks, ensuring optimal efficiency and output.

For feedstocks with bromine concentrations below 3 gpl, a cold process is recommended, while feedstocks above 3 gpl are better suited for a hot process.

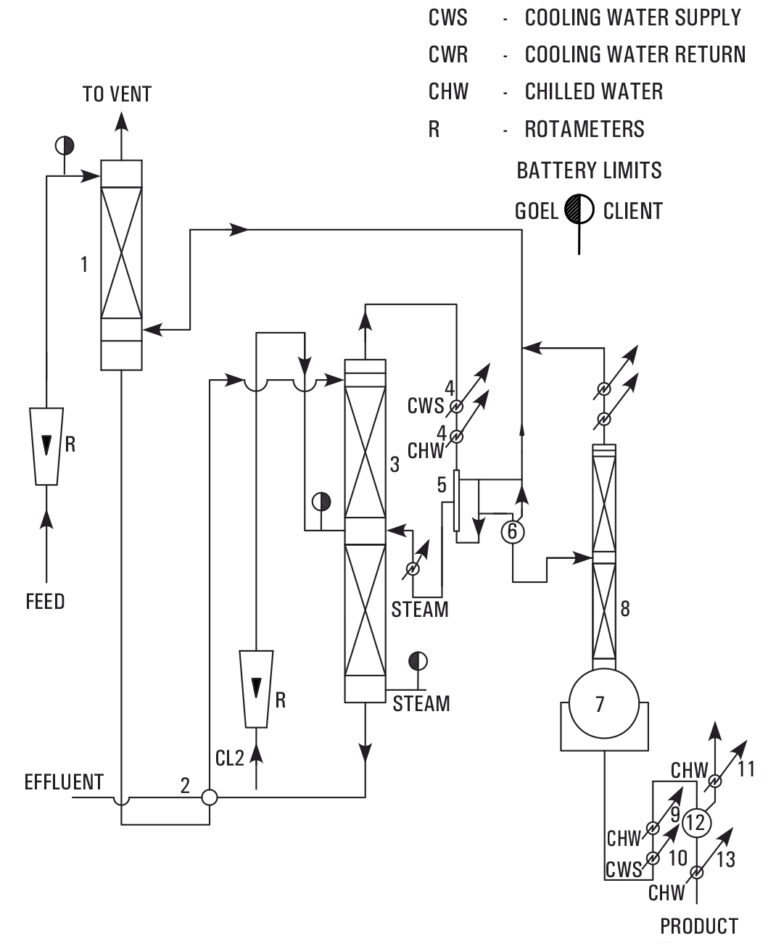

A schematic of the Bromine Recovery Unit is available for reference.

The bromine recovery process involves simultaneous chlorination and steam distillation. The acidic feedstock is first preheated in a feed preheater to near its boiling point. It is then introduced into the main column, where chlorine and steam are blown in simultaneously.

Chlorine reacts with the feedstock to release bromine, which is distilled along with steam. The resulting mixture of bromine, steam, and excess chlorine is condensed in the condenser. The condensate is passed through a gravity separator, where bromine is separated from bromine water.

During the purification stage in the bromine column, the aqueous layer is recycled back into the main column for further processing.

Crude bromine is purified under reflux conditions, and pure bromine is collected in the receiver. Any remaining vapors are treated in a tail scrubber to recover trace amounts of bromine, ensuring maximum yield.

Goel’s expertise ensures that every Bromine Recovery Plant is designed for high efficiency, reliability, and compliance with industrial standards.

| SR. | DESCRIPTION | SR. | DESCRIPTION | |

| 1 | TAIL SCRUBBER | 7 | REBOLIER | |

| 2 | FEED PREHEATER | 8 | PURIFICATION COLUMN | |

| 3 | Br STRIPPING COLUMN | 9 | PRODUCT COOLER | |

| 4 | Br CONDENSERS | 10 | PRODUCT COOLER | |

| 5 | PHASE SEPERATOR | 11 | VENT CONDENSER | |

| 6 | CRUDE Br RECEIVING VESSEL | 12 | PRODUCT RECEIVER VESSEL | |

| 13 | PRODUCT COOLER |