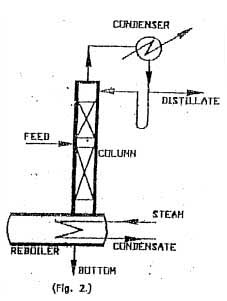

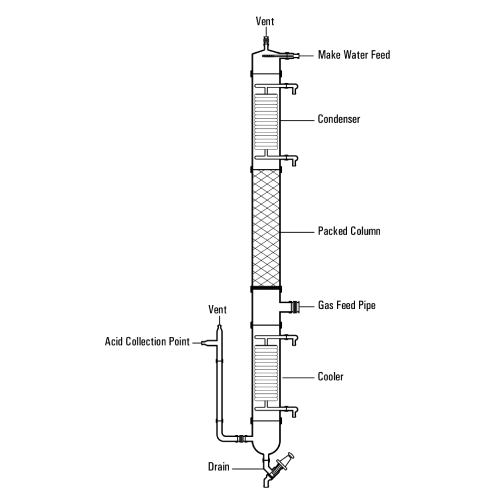

Batch distillation processes have inherent limitations that are effectively overcome by a Continuous Distillation System. A typical fractionating column, as shown in figure 2, consists of distinct rectifying and stripping sections designed for uninterrupted operation.

In this setup, the feed is continuously introduced into the column, while the top and bottom products are simultaneously withdrawn. The process operates automatically by maintaining steady feed and utility flow rates, ensuring consistent separation.

For multicomponent mixtures requiring more than two products, multiple columns are necessary. Each column in a Distillation System is capable of producing only two products: one in relatively pure form and the other containing the remaining components.

The second product is then directed to a subsequent column, where further separation occurs. This column-by-column process continues until the system reduces to a binary mixture, allowing both components to be fully separated in the final column.

A key principle in designing a Continuous Distillation System is that for complete separation of an n-component mixture, a total of n–1 fractionating columns are required.

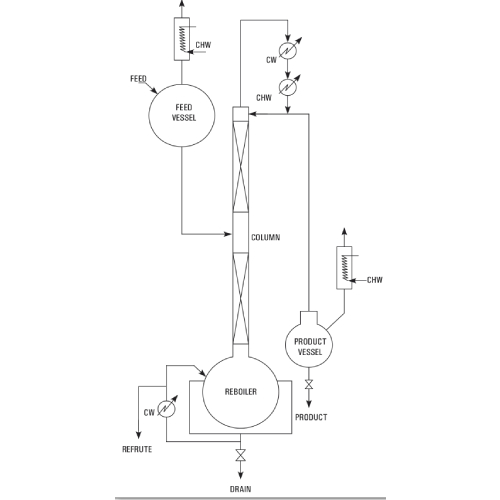

The decision on which product to obtain in relatively pure form depends on the relative volatility of the components in the feed. For instance, consider a ternary mixture containing components A, B, and C, where A is the most volatile.

To isolate all three substances in substantially pure form, different distillation schemes, as illustrated in figure 3, can be applied. The choice of scheme depends on the relative ease or difficulty of separating components and the specific operational principles of distillation. In most cases, scheme (b) is preferred, as it requires fewer vaporization steps for the most volatile component, A.