Commercial Hydrochloric Acid is commonly available in the market as a 30% aqueous solution. However, certain industries such as bulk drug and pharmaceutical manufacturing require Hydrochloric Acid in an anhydrous or moisture-free form for precise and critical reactions. In such applications, moisture cannot be tolerated, and therefore, users rely on in-house systems to generate anhydrous HCL gas from commercial-grade Hydrochloric Acid for their own use.

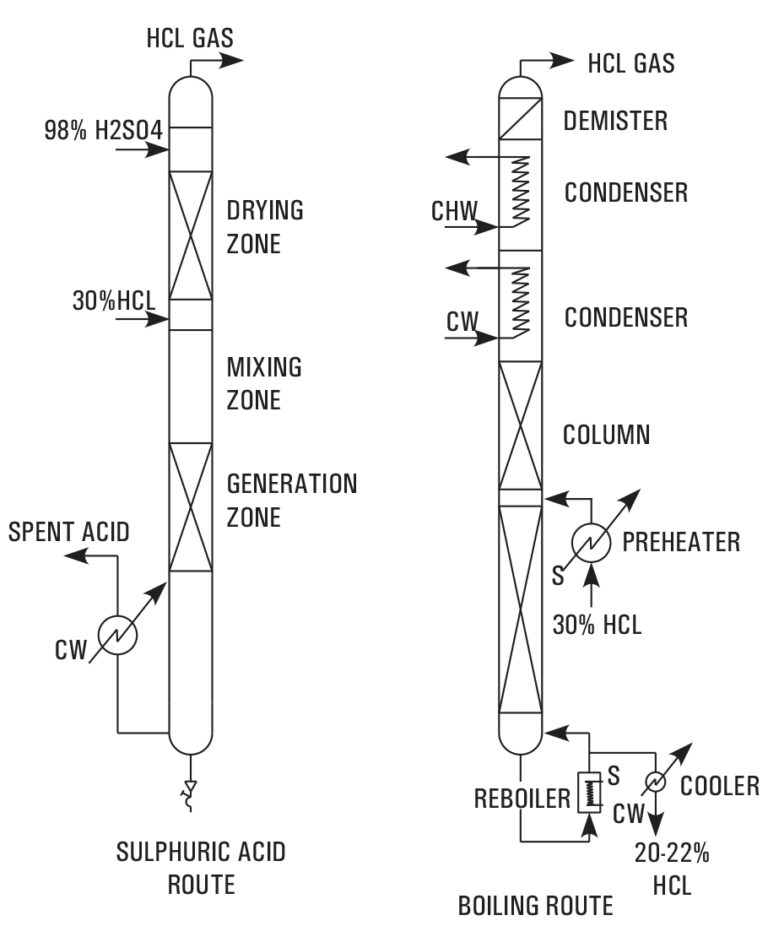

Different techniques are used across industries for generating HCL gas. Among them, the Sulphuric Acid Route and the Boiling Route are the most established processes. At GlassReactor, we also provide the Calcium Chloride Route for efficient and environmentally safe HCL Gas Generation.

|

Route |

Sulphuric Acid Route |

Boiling Route |

||

|

Working Principle |

Hydrochloric acid is highly soluble in water but the solubility diminishes in presence of H2SO4 and at 70 to 75% H2SO4 concentration its solubility is negligible. Thus by adding (98%) commercial Sulphuric acid to commercial hydrochloric acid (30%) in proper ratio the entire HCL can be liberated in gaseous form leaving 75% H2SO4 as spent acid. |

Aqueous hydrochloric acid forms a maximum boiling point azeotrope at 110 C containing 20.24% HCL at atmospheric pressure. Thus by distilling commercial hydrochloric acid (30%) pure HCL gas can be generated and spent acid will contain over 20.24% HCL. |

||

|

Process Outline |

Metered quantities of commercial sulphuric acid hydrochloric acids are fed to the unit where they mix in the Mixing Zone. The gas generated forms a froth and enters the Generation Zone where while traveling through a bed gas is released which travels upwards through the Drying Zone. Here the gas comes in intimate contact with downward flow of 98% H2SO4. The dry gas leaving the unit passes through a rotameter. The spent liquor containing 70-75% H2SO4 passes through the Cooling Zone before being discharged. |

Metered quantity of commercial hydrochloric acid is preheated in a preheater by steam and fed to a fractionating column with steam as heating media in the reboiler. The vapours leaving the column are condensed with coolant as cooling water and chilled brine in stages. The relatively dry gas passes through a mist eliminator and then through a rotameter. The spent acid containing 22% HCL is cooled through a cooler and then discharged. |

||

|

Salient Features |

– Operational reliability the unit can be started / stopped in seconds. |

– Operational reliability. |

||

|

Indicative Raw-material & Utilities for 20 kg/hr HCL |

30% HCL – 70 kg/hr |

30% HCl – 200 kg/hr |

||

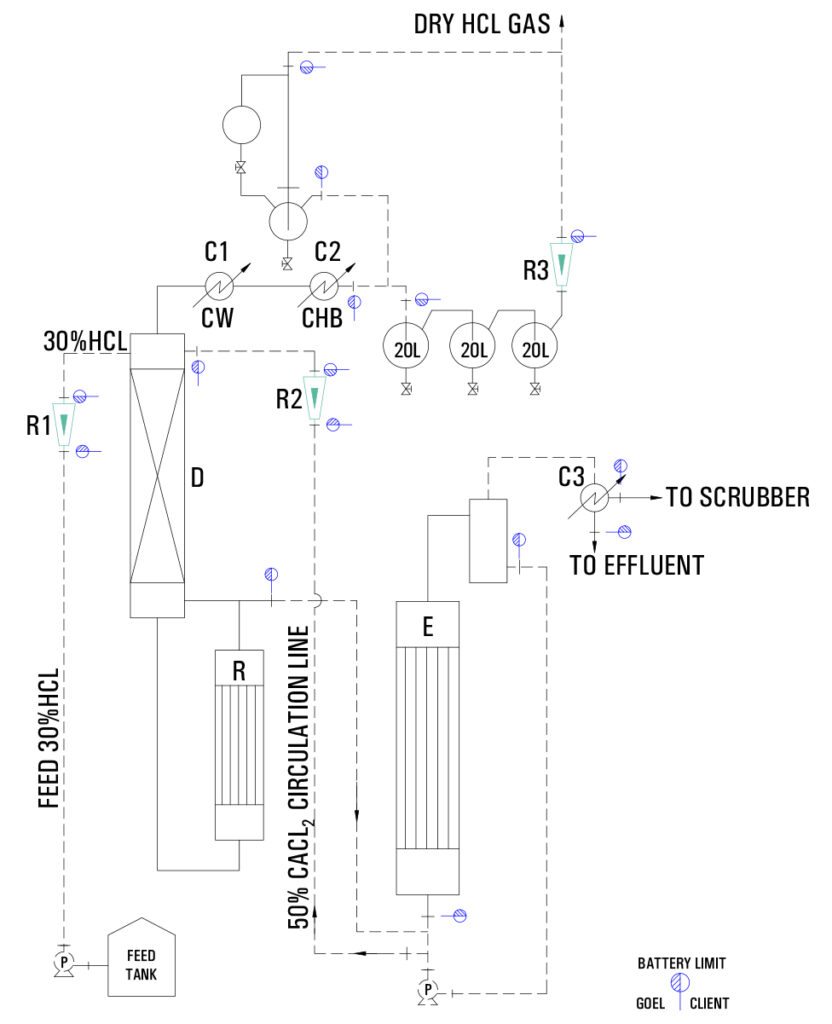

Hydrochloric Acid and water form a constant boiling mixture (azeotrope) at around 110°C, corresponding to a concentration of about 20.24% HCL by weight. When concentrated Calcium Chloride solution is added to commercial Hydrochloric Acid, this azeotropic point is removed, allowing complete liberation of HCL gas through distillation. This method ensures the production of anhydrous HCL gas in a clean and eco-friendly manner, making it the most sustainable option for Dry HCL Gas Generation Systems.

Calcium Chloride Route Process Description:

In the Calcium Chloride Route, metered quantities of commercial-grade Hydrochloric Acid and a 50% Calcium Chloride solution are fed into a stripping column that is equipped with a steam-heated reboiler. The effluent discharged from the column bottom is a dilute acidic Calcium Chloride solution. This solution is concentrated back to 50% using an evaporator and then recirculated into the process, minimizing waste and improving efficiency.

The vapor generated is condensed in stages using cooling water followed by chilled brine as the coolant. The dry HCL gas obtained passes through a mist eliminator and then through a rotameter before being delivered to the point of use. This setup ensures consistent and high-purity gas output for all downstream applications.

RAW MATERIAL AND UTILITY REQUIREMENTS:

The following are the indicative requirements for a 20 Kg/hr HCL Gas Generator system.

| 1 | 30-32 % HCl, (Kg/hr) | : 66 |

| 2 | Cooling water at 30 째C (M /hr)) | : 4 |

| 3 | Chilled brine at -10 째C (M /hr) | : 3 |

| 4 | Steam at 6 Kg/cm (g) | : 150 |

Our Anhydrous Dry HCL Gas Generation System is engineered for reliable performance, easy operation, and minimal environmental impact, making it an ideal choice for laboratories, chemical plants, and pharmaceutical production facilities.

|

LEGEND |

||||

|

R |

– |

REBOILER |

||

|

C |

– |

COLUMN |

||

|

E |

– |

EVAPORATOR |

||

|

PH |

– |

PRIMARY CONDENSER |

||

|

SH |

–

|

SECONDARY CONDENSER |

||

|

H |

– |

CONDENSER |

||

|

ME |

– |

MIST ELIMENATOR |

||

|

P |

– |

PUMP |

||

|

CW |

– |

COOLING WATER |

||

|

CHB |

– |

CHILLED DRAINE |

||

|

S |

– |

STEAM |

||

|

C |

– |

CONDENSATE |

||