Commercial-grade sulphuric acid is inexpensive but often generated in a dilute or contaminated form that limits its reuse and market value.

Neutralizing such acid with lime leads to solid waste (calcium sulphate) handling issues and increases operational costs.

To address these challenges, Goel Impex provides complete design and engineering solutions for sulphuric acid concentration systems. These systems recover dilute acid and reconcentrate it to the required strength, allowing industries to reuse it efficiently. This approach not only eliminates disposal problems but also reduces the consumption of fresh sulphuric acid.

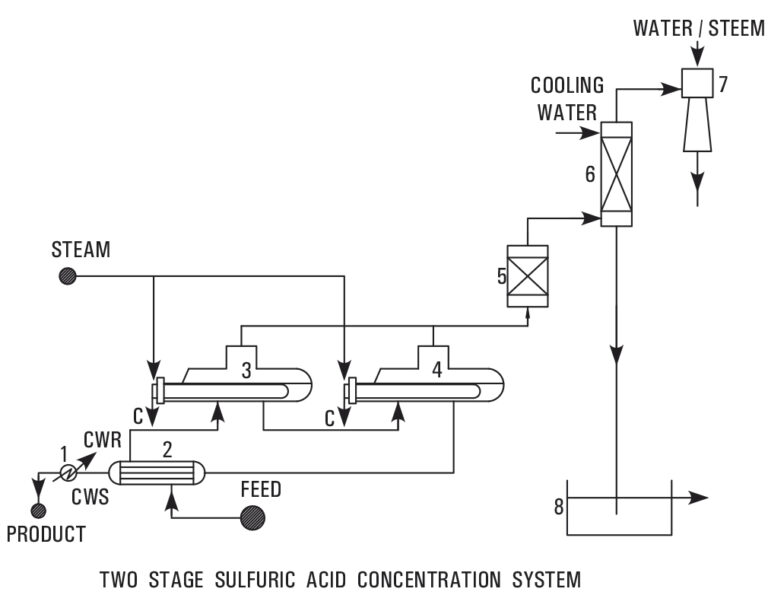

The process is straightforward and involves the concentration of dilute sulphuric acid through evaporation under a controlled vacuum. Steam or thermic fluid is used as the heating medium. The feed acid is first preheated and then passed through multiple evaporation stages to achieve the target concentration.

The vapors generated during the process are condensed and discharged via barometric legs, while non-condensable gases are removed using an ejector. The concentrated acid is then cooled and collected in a storage vessel for reuse.

The utilities required such as steam or thermic fluid, cooling water, and electrical power depend on parameters like feed rate, initial concentration, and final concentration desired.

For instance, in a 50 TPD plant processing a 50% H₂SO₄ feed to achieve 70% concentration, the utility consumption is determined based on these operational variables.

| 1 | Steam@ 6 bar{g) pressure | : 800 Kg/hr |

| 2 | Cooling water @ 30 째C | : 70 Cu M/hr |

| 3 | Power | : 15 KW |

|

KEY |

||||

|

1 |

– |

PRODUCT COOLER |

||

|

2 |

– |

FEED PREHEATER |

||

|

3 |

– |

1ST, STAGE EVAPORATOR |

||

|

4 |

– |

2ND, STAGE EVAPORATOR |

||

|

5 |

– |

MIST ELIMINATOR |

||

|

6 |

– |

DIRECT COOLER |

||

|

7 |

– |

EJECTION |

||

|

8 |

– |

SEAL POT |

||

|

C |

– |

STEAM CONDENSATE |

||

|

CWS |

– |

COOLING WATER SUPPLY |

||

|

CWR |

– |

COOLING WATER RETURN |

||

Goel Impex specializes in the design and supply of sulphuric acid concentration plants for chemical, pharmaceutical, and industrial applications. Each system is engineered for efficient recovery and concentration of sulphuric acid, ensuring reliability and cost savings.

The plant incorporates essential components such as a distillation column, reboiler, condenser, heat exchanger, and other precision glass equipment. Designed for operation at reduced pressure and temperature, the plant ensures safe, steady, and energy-efficient performance.

All key components are fabricated using borosilicate glass, known for its resistance to chemical corrosion and thermal stress. The transparency of the glass equipment also enables easy observation and monitoring during operation.

The sulphuric acid concentration unit is capable of processing acid solutions from 50% to 98% concentration. It supports continuous operation with minimal downtime for maintenance or cleaning.

The distillation column is filled with premium packing material to ensure optimal surface area for efficient mass transfer. The heat exchanger design ensures maximum heat recovery, reducing both energy usage and operational costs.

Safety is built into every stage of the plant. The system is equipped with pressure relief devices, automated control systems, emergency shutdown features, and advanced monitoring instruments to ensure operator safety and reliable operation.

Goel Impex provides complete support from design to commissioning. This includes installation, start-up assistance, and operator training to ensure smooth and safe plant operation. Comprehensive after-sales maintenance and technical support are also available to help clients maintain peak plant performance.

With a focus on quality, safety, and sustainability, Goel Impex’s Sulphuric Acid Concentration Systems offer industries a dependable solution for acid recovery and reuse. Built with advanced glass engineering and supported by expert process design, these systems deliver long-term efficiency, reliability, and environmental benefits.