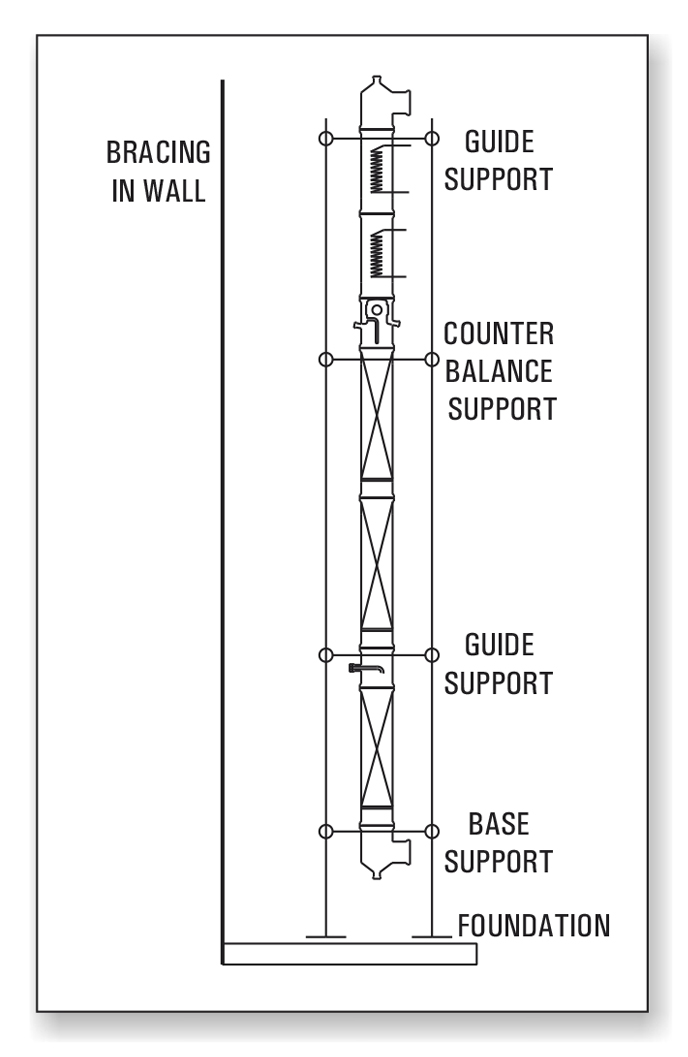

Glass plants and pipeline should be supported correctly. To prevent inducing undesirable stresses in the glass, support should be rigid. When supported, glass should be in compression.

Generally, glass plant and equipment are supported in a rectangular tubular structure. This structure is formed of galvenised mild steel tubing with the cast iron fittings which are described in this catalogue. This type of structure provides enough flexibility for future modifications and is strong enough to support a glass unit.

Following rules should be followed while supporting a glass unit in a tubular structure:

1. The structure must be rigid. To give lateral support it must be braced back to the nearest wall or any rigid feature.

2. All glass columns are build up from a fixed point on which whole weight of the column should be taken. If total loads exceeds the permissible limits, counter balance supports should be used to relieve excessive weight.

3. With change in temperature, glass column and tubular structure expands at different rate. Therefore glass unit must be free for vertical movement above the fixed point. Hence, above the fixed point, guides supports should be used to give lateral support.

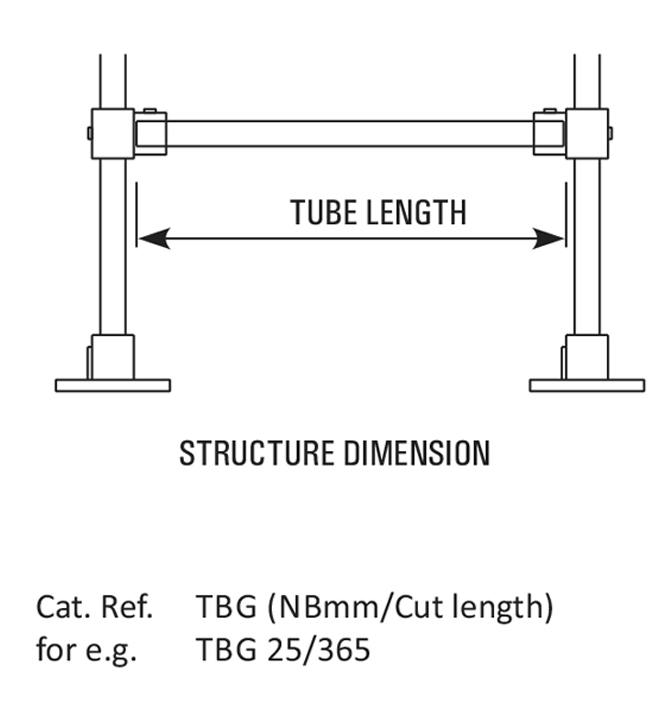

For forming the structure,”B” class galvanised tubes, Mild Steel with Epoxy Coated, Stainless Steel 304 & 316 are used in size of 1/2″, 1″, 1.1/4″, 1.1/2″ and 2″. Cut tubes are available in required length to form a standard size structure. Cut tubes are provided with rubber plug at both the ends.

|

NB Inches |

NB mm |

External Diameter |

|

|

1/2″ |

15 |

19.5 |

|

|

1″ |

25 |

32.5 |

|

|

1.1/4″ |

30 |

41.5 |

|

|

1.1/2″ |

40 |

48.3 |

|

|

2″ |

50 |

60.3 |

|

|

Structure |

NB (mm) |

||||

|

Dimension |

15* |

25* |

30* |

40* |

50* |

|

2500 |

– |

2500 |

– |

– |

– |

|

3000 |

– |

3000 |

3000 |

– |

– |

|

3500 |

– |

3500 |

3500 |

– |

– |

|

4000 |

– |

– |

4000 |

– |

– |

|

000 |

– |

6000 |

6000 |

6000 |

6000 |

|

400 |

– |

365 |

355 |

345 |

335 |

|

500 |

– |

465 |

455 |

445 |

435 |

|

600 |

– |

565 |

555 |

545 |

535 |

|

800 |

– |

765 |

755 |

745 |

735 |

|

1000 |

– |

965 |

955 |

945 |

935 |

|

1200 |

– |

1165 |

1155 |

1145 |

1135 |

|

1500 |

– |

1465 |

1455 |

1445 |

1435 |

|

400 |

435 |

445 |

445 |

455 |

465 |

|

500 |

535 |

545 |

545 |

555 |

565 |

|

600 |

635 |

645 |

645 |

655 |

665 |

|

800 |

835 |

845 |

845 |

855 |

865 |

|

1000 |

1035 |

1045 |

1045 |

1055 |

1065 |

|

1200 |

1235 |

1245 |

1245 |

1255 |

1265 |

|

1500 |

1535 |

1545 |

1545 |

1555 |

1565 |

Following structure fittings are available to use with galvanised tubes in order to form a tubular structure for a glass plant. These fittings are made of cast iron. Also available in Stainless Steel 304 & 316 and are suitable to the galvanised tubes described earlier.

These slidable fittings are provided with grub screws to fix it at required position on a galvanised tube.

These fittings are specially made to construct a tubular structure which provides enough flexibility for future modifications without involving any hammering and welding.

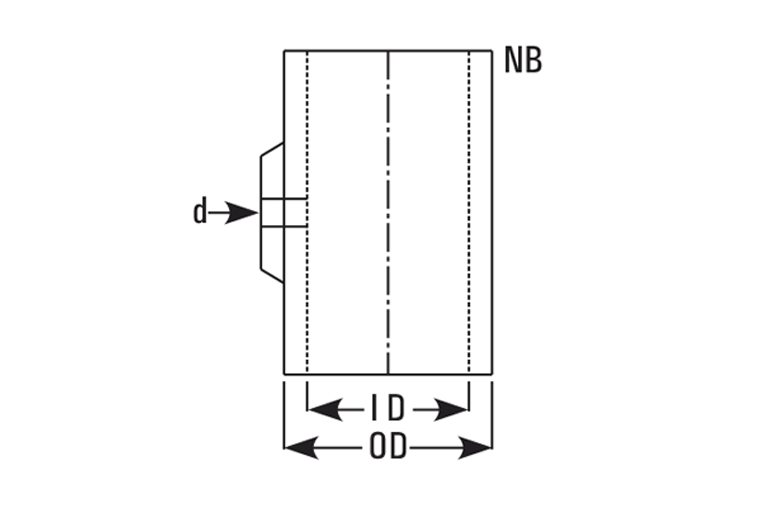

|

NB |

TUBE DIA |

ID |

OD |

d |

|

25 |

32.5 |

35 |

45 |

1/2″ |

|

30 |

42.5 |

45 |

55 |

1/2″ |

|

40 |

48.3 |

51 |

61 |

1/2″ |

|

50 |

60.3 |

63 |

73 |

1/2″ |

|

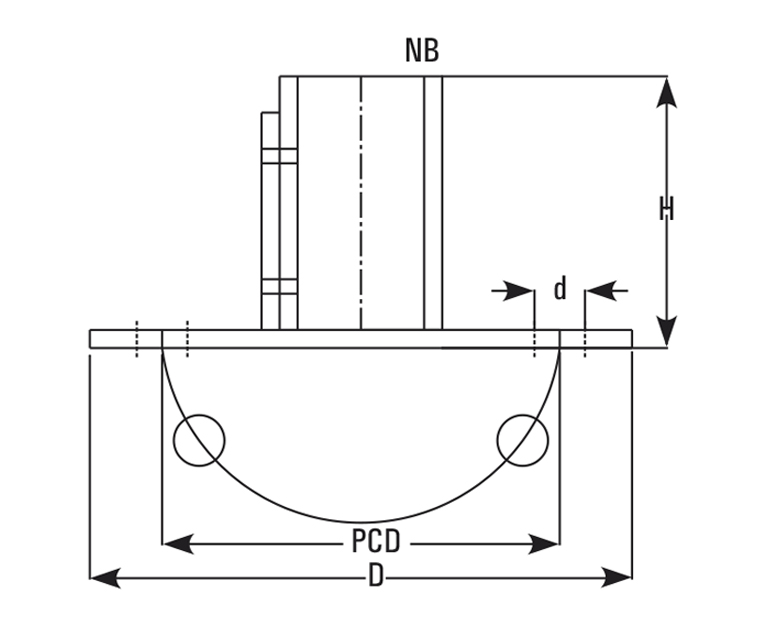

Cat.Ref. |

NB |

D |

H |

PCD |

dØ |

|

BS25* |

25 |

150 |

75 |

110 |

4 x 14Ø |

|

BS30* |

30 |

150 |

75 |

110 |

4 x 14Ø |

|

BS40 |

40 |

150 |

75 |

110 |

4 x 14Ø |

|

BS50 |

50 |

175 |

75 |

125 |

4 x 14Ø |

|

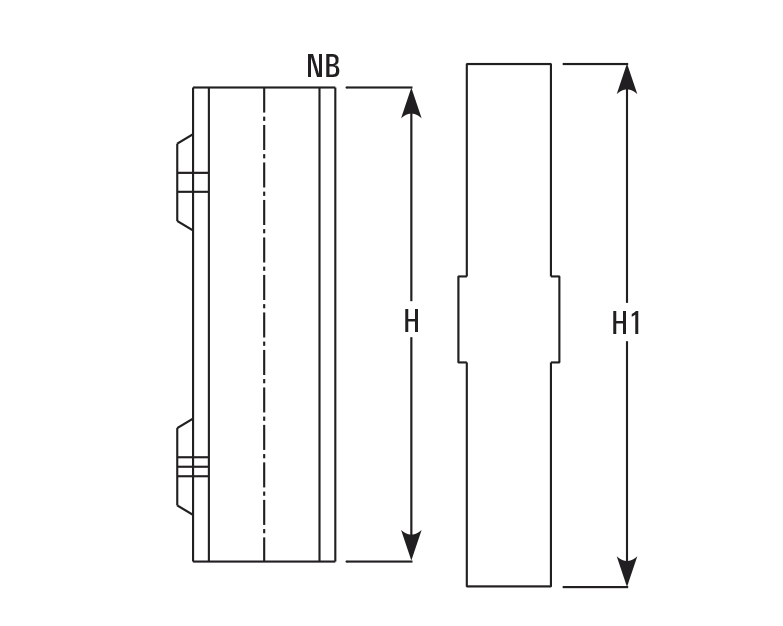

Cat.Ref. |

NB |

H

|

H1 |

|

CL25 |

25 |

150 |

200 |

|

CL30 |

30 |

150 |

200 |

|

CL40 |

40 |

150 |

200 |

|

CL50 |

50 |

150 |

200 |

|

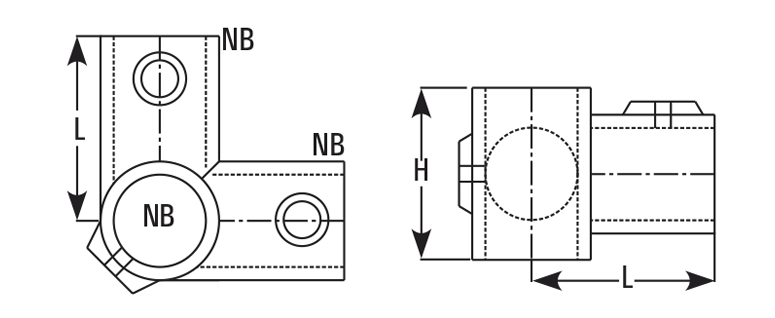

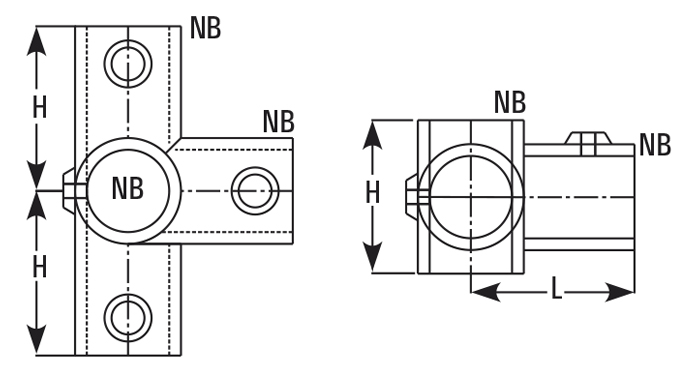

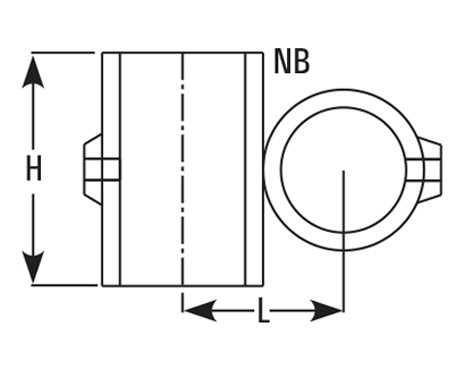

Cat.Ref. |

NB |

H |

L |

|

BN25* |

25 |

50 |

55 |

|

BN30* |

30 |

65 |

70 |

|

BN40 |

40 |

70 |

80 |

|

BN50 |

50 |

85 |

95 |

|

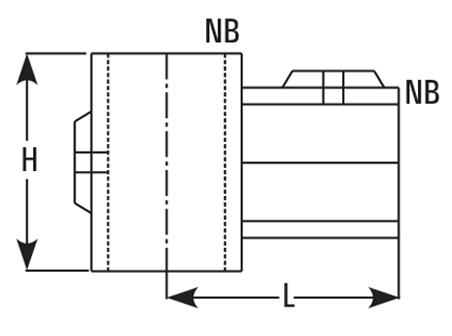

Cat.Ref. |

NB |

H |

L |

|

T25* |

25 |

50 |

55 |

|

T30* |

30 |

65 |

70 |

|

T40 |

40 |

70 |

80 |

|

T50 |

50 |

85 |

95 |

|

Cat.Ref. |

NB |

H |

L |

|

BN25 |

25 |

50 |

55 |

|

BN30 |

30 |

65 |

70 |

|

BN40 |

40 |

70 |

80 |

|

BN50 |

50 |

85 |

95 |

|

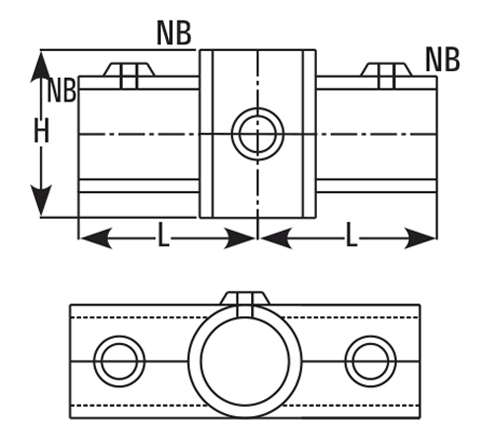

Cat.Ref. |

NB |

H |

L |

|

DT25 |

25 |

50 |

55 |

|

DT30 |

30 |

65 |

70 |

|

DT40 |

40 |

70 |

80 |

|

DT50 |

50 |

85 |

95 |

|

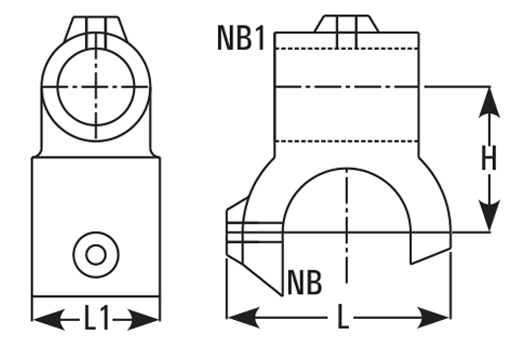

Cat.Ref. |

NB |

h |

L |

L1 |

|

EBT25* |

25 |

40 |

65 |

50 |

|

EBT30* |

30 |

52 |

75 |

60 |

|

EBT40 |

40 |

62 |

85 |

60 |

|

EBT50 |

50 |

72 |

95 |

60 |

|

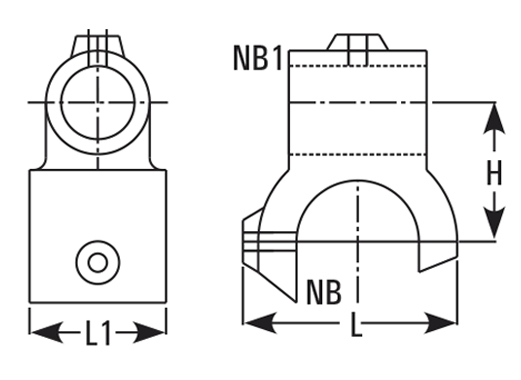

Cat.Ref. |

NB |

NB1 |

H |

L |

L1 |

|

UBT25/15* |

25 |

15 |

35 |

65 |

50 |

|

UBT30/15* |

30 |

15 |

40 |

75 |

60 |

|

UBT40/25 |

40 |

25 |

50 |

85 |

60 |

|

UBT50/25 |

50 |

25 |

55 |

95 |

60 |

|

Cat.Ref. |

NB |

H |

L |

|

X25 |

25 |

50 |

45 |

|

X30 |

30 |

65 |

55 |

|

X40 |

40 |

65 |

70 |

|

X50 |

50 |

65 |

85 |

|

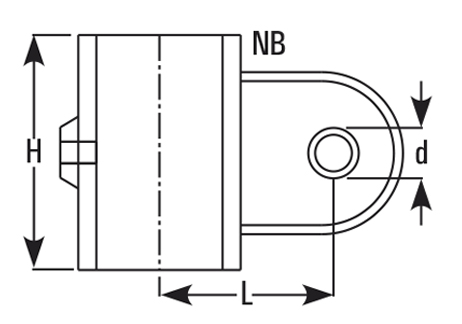

Cat.Ref. |

NB |

h |

L |

d |

|

SPT15* |

15 |

40 |

35 |

13 |

|

SPT25* |

25 |

55 |

50 |

13 |

|

SPT30* |

30 |

55 |

57 |

13 |

|

SPT40 |

40 |

55 |

62 |

13 |

|

SPT50 |

50 |

55 |

67 |

13 |

|

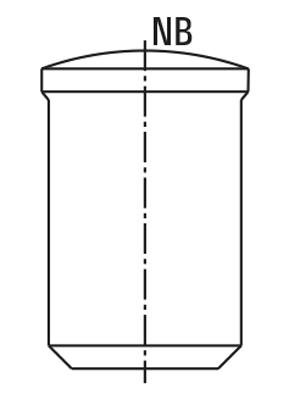

Cat.Ref. |

NB |

|

PLUG15* |

15 |

|

PLUG25* |

25 |

|

PLUG30* |

30 |

|

PLUG40 |

40 |

|

PLUG59 |

50 |

|

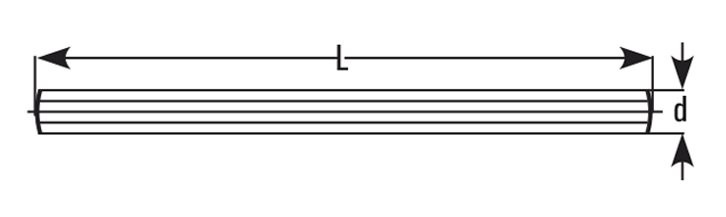

Cat.Ref. |

d |

L |

|

|

STUD5/16-150* |

5/16″ |

150 |

|

|

STUD3/8-150* |

3/8″ |

150 |

|

|

STUD1/2-200 |

1/2″ |

200 |

|

|

DN |

Recommended tube size NB (mm) |

Minimum Structure size Depth X Width |

|

|

80 |

25 |

500 x 500 |

|

|

100 |

25 |

500 x 500 |

|

|

150 |

25,30 |

600 x 600 |

|

|

225 |

30 |

800 x 800 |

|

|

300 |

30 |

800 x 800 |

|

|

400 |

30 |

1000 x 1000 |

|

|

450 |

30,40 |

1000 x 1000 |

|

|

600 |

40,50 |

1200 x 1200 |

|

|

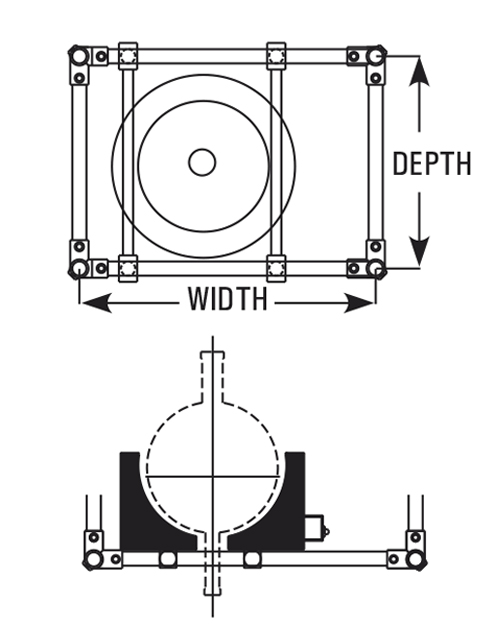

Size (Liters) |

Recommended tube size NB (mm) |

Minimum Structure size Depth X Width |

|

|

20 |

25 |

400 x 600 |

|

|

50 |

25 |

600 x 800 |

|

|

100 |

25,30 |

800 x 800 |

|

|

200 |

30 |

800 x 1000 |

|

|

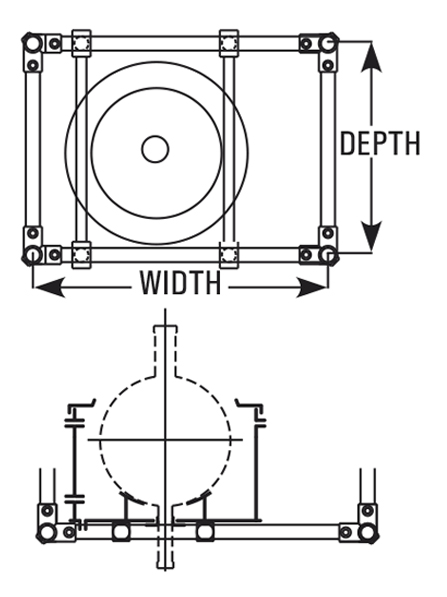

Size (Litres) |

Recommended tube size NB (mm) |

Minimum Structure size Depth X Width |

|

|

20 |

25 |

500 x 600 |

|

|

50 |

25 |

600 x 800 |

|

|

100 |

25,30 |

800 x 1000 |

|

|

200 |

30 |

800 x 1200 |

|

|

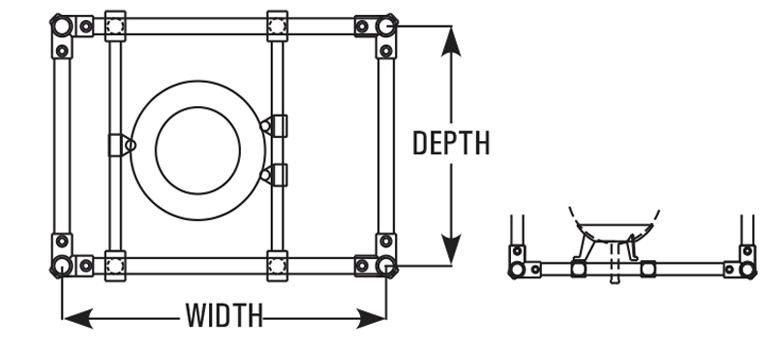

Size (Litres) |

Recommended tube size NB (mm) |

Minimum Structure size Depth X Width |

|

|

20 |

25 |

500 x 600 |

|

|

50 |

25 |

600 x 800 |

|

|

100 |

25,30 |

1000 x 1000 |

|

|

200 |

30 |

1000 x 1000 |

|

|

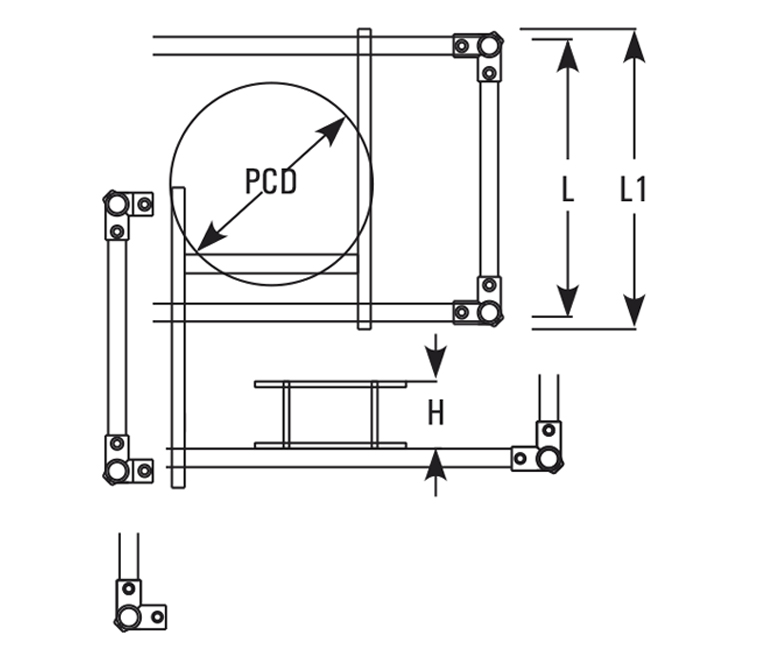

Cat. Ref. |

PCD |

L1 |

L |

H |

|

FCSH225 |

310 |

1000 |

800 |

75 |

|

FCSH300 |

395 |

1000 |

800 |

75 |

|

FCSH400 |

495 |

1200 |

1000 |

75 |

|

FCSH450 |

585 |

1200 |

1000 |

100 |

|

FCSH600 |

710 |

1400 |

1200 |

100 |